- Home

- Knowledge Base

- Gravity Casting BLOG

- The Powerhouse of Electric Vehicle Manufacturing: Gravity Casting in Aluminum Components

With the booming electric vehicle (EV) market, the production of high-quality and high-performance components has become increasingly vital for EV manufacturers. Gravity casting technology has emerged as a key element in manufacturing aluminum alloy components for electric vehicles. Gravity casting, based on gravitational force, involves injecting molten aluminum alloy into molds, ensuring uniform filling, shaping, and cooling of components. This process achieves high material density, structural strength, and consistent surface quality.

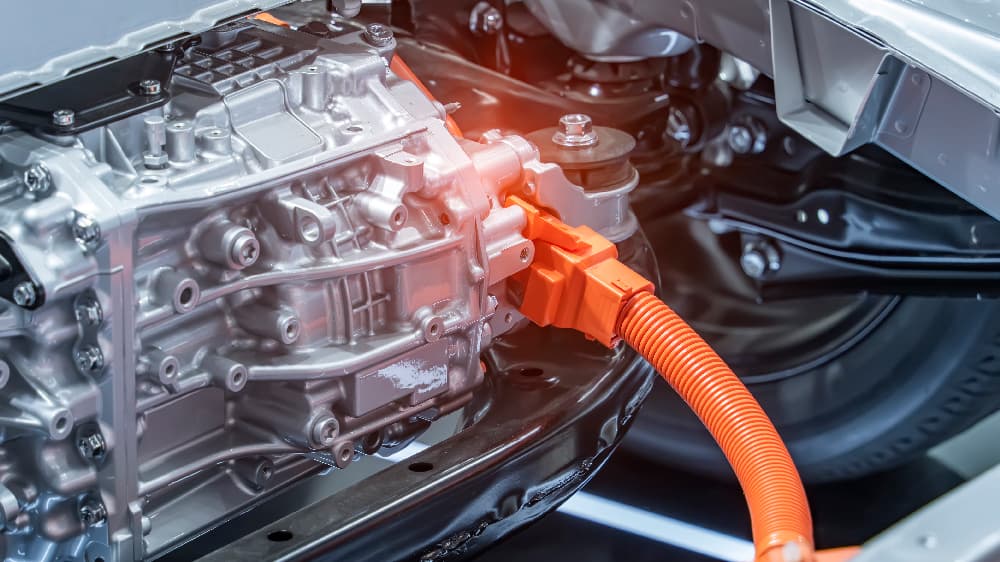

Gravity casting finds widespread application in the production of aluminum components for electric vehicles, including motor housings, battery casings, chassis assemblies, and more. Aluminum components are favored in the EV industry due to their lightweight nature, high strength, and excellent heat conductivity. Gravity casting technology ensures the fulfillment of these requirements and allows for the production of complex-shaped components, providing greater design freedom.

Motor Housings

First and foremost, gravity casting yields high-quality finished products with excellent surface quality and dimensional accuracy, reducing the need for subsequent machining processes. Secondly, this process efficiently utilizes aluminum materials, facilitating lightweight component design, which improves the energy efficiency and driving range of electric vehicles. Additionally, gravity casting boasts high production efficiency, enabling large-scale production and short lead times, meeting the rapid growth demands of the EV market.

As the electric vehicle industry continues to evolve, gravity casting technology undergoes ongoing innovation and improvement. Future developments will introduce more material options and enhanced mold designs tailored to the aluminum components required for electric vehicles. Furthermore, integration with other manufacturing technologies such as 3D printing and computer-aided design will drive the application and development of gravity casting technology, resulting in higher performance and optimized manufacturing of aluminum components for electric vehicles.

Gravity casting technology plays a crucial role in the production of electric vehicle components, offering high-quality and high-performance solutions. Through gravity casting, we obtain components with superior structural strength and design flexibility while achieving energy efficiency and reduced carbon emissions. Future advancements will bring about more innovation and progress, propelling the application of gravity casting technology in the electric vehicle industry and driving the growth of the entire sector.

View more information about our electric vehicle components manufacturing with gravity casting.